How to choose the right swimming pool pump for my needs? It’s a question many pool owners grapple with, and rightfully so! The pump is the heart of your pool’s filtration system, impacting everything from water clarity and energy bills to the overall longevity of your equipment. Choosing wisely means understanding your pool’s specific needs, exploring different pump types and their capabilities, and considering factors like flow rate, horsepower, and budget.

Let’s dive in and find the perfect pump for your aquatic oasis.

This guide breaks down the process into manageable steps, helping you navigate the world of single-speed, two-speed, and variable-speed pumps. We’ll examine the importance of matching pump performance to your pool’s size, shape, and filtration system. We’ll also cover crucial aspects like energy efficiency, maintenance costs, and the long-term value of investing in a high-quality pump. By the end, you’ll be equipped to make an informed decision and enjoy years of sparkling clean water.

Understanding Your Pool’s Needs

Source: ytimg.com

Choosing the right swimming pool pump hinges on understanding your pool’s specific characteristics. Factors like size, shape, surface type, and water volume all significantly impact the pump’s required flow rate and horsepower. Ignoring these factors can lead to an underpowered pump (resulting in poor circulation and filtration) or an overpowered pump (leading to unnecessary energy consumption and potential damage).

Pool Size and Shape

The dimensions and shape of your pool directly influence the volume of water it holds and, consequently, the pump’s workload. Larger pools, naturally, require more powerful pumps to effectively circulate and filter the water. Irregular shapes, with many curves and angles, may also demand a more powerful pump compared to a simple rectangular pool of the same volume, due to the increased resistance to water flow.

For example, a kidney-shaped pool might require a slightly larger pump than a rectangular pool of the same surface area to ensure adequate circulation in all areas.

Pool Surface Type

Different pool surfaces offer varying degrees of friction, affecting the pump’s performance. Concrete pools, for instance, tend to have a rougher surface than vinyl-lined pools. This increased friction requires a pump with a higher flow rate to overcome the resistance and maintain proper circulation. Conversely, a smooth vinyl liner presents less friction, allowing for potentially lower horsepower requirements.

The material of the pool surface influences the pump’s energy consumption as well, with rougher surfaces leading to higher energy needs.

Water Volume and Pump Flow Rate

The volume of water in your pool is paramount in determining the necessary pump flow rate. A larger pool with a greater water volume necessitates a pump with a higher flow rate to ensure complete filtration and circulation within a reasonable timeframe. Flow rate is typically measured in gallons per minute (GPM). As a general rule, you should aim for a pump that can completely circulate your pool’s water at least once every 6-8 hours.

This circulation time is crucial for maintaining water quality and preventing algae growth. For example, a 15,000-gallon pool would require a pump with a significantly higher GPM than a 5,000-gallon pool.

Recommended Pump Horsepower Ranges

The following table provides a general guideline for selecting the appropriate pump horsepower based on pool type, size, and estimated water volume. Remember that these are estimates, and specific requirements may vary depending on individual pool design and desired circulation times. Always consult with a pool professional for precise recommendations.

| Pool Type | Typical Size (sq ft) | Approximate Water Volume (gallons) | Recommended Horsepower Range |

|---|---|---|---|

| In-ground Concrete | 500-1000 | 10,000-20,000 | 1-1.5 hp |

| In-ground Vinyl Liner | 400-800 | 8,000-16,000 | 0.75-1.25 hp |

| Above-ground (Round) | 200-400 | 4,000-8,000 | 0.5-1 hp |

| Above-ground (Oval) | 300-600 | 6,000-12,000 | 0.75-1.5 hp |

Pump Types and Their Capabilities

Choosing the right swimming pool pump involves understanding the different types available and how their performance characteristics impact your pool’s operation and your energy bill. This section will delve into the specifics of single-speed, two-speed, and variable-speed pumps, comparing their energy efficiency, material composition, and maintenance requirements.

Single-Speed, Two-Speed, and Variable-Speed Pump Performance

Single-speed pumps run at a constant speed, providing consistent flow but often at the cost of energy efficiency. Two-speed pumps offer two distinct speed settings, allowing for flexibility in flow rate depending on the need (e.g., higher speed for cleaning, lower speed for filtration). Variable-speed pumps provide the most control, allowing for infinitely adjustable speed settings optimized for various tasks and energy conservation.

The key performance difference lies in the adaptability and precision of flow control. Variable-speed pumps offer the most precise control, followed by two-speed, and finally, single-speed pumps offer the least. This translates to better cleaning efficiency and more targeted water circulation with the more advanced models.

Energy Efficiency of Different Pump Types

Single-speed pumps are generally the least energy-efficient. They run continuously at their maximum speed, consuming a significant amount of electricity. Two-speed pumps offer some improvement, as you can select a lower speed for less demanding tasks. However, variable-speed pumps excel in energy efficiency. They adjust their speed based on the demands of the pool, consuming only the necessary energy.For example, consider a single-speed pump running continuously at 1.5 horsepower (hp) for 8 hours a day.

Assuming an electricity cost of $0.15 per kilowatt-hour (kWh) and a conversion factor of 0.746 kW per hp, the daily energy cost would be approximately $1.79. A variable-speed pump, however, might only run at 0.5 hp for 8 hours during normal filtration and at a higher speed for a shorter period during cleaning. This could reduce the daily energy cost to, for instance, $0.89, representing a significant saving.

These figures are illustrative; actual savings depend on usage patterns and pump specifications.

Pump Material Advantages and Disadvantages, How to choose the right swimming pool pump for my needs

Swimming pool pumps are commonly constructed from stainless steel or plastic. Stainless steel pumps are generally more durable and resistant to corrosion, making them a longer-lasting investment. However, they are also more expensive upfront. Plastic pumps, conversely, are more affordable but may be less durable and susceptible to damage from chemicals or extreme temperatures. The choice depends on budget, longevity expectations, and the specific pool environment.

Comparison Table of Pump Types

| Pump Type | Pros | Cons | Maintenance |

|---|---|---|---|

| Single-Speed | Simple, inexpensive | High energy consumption, less versatile | Regular cleaning and occasional motor replacement |

| Two-Speed | More energy-efficient than single-speed, some flow rate flexibility | Less energy-efficient than variable-speed, limited speed options | Similar to single-speed, with occasional switch maintenance |

| Variable-Speed | Highly energy-efficient, precise flow control, quieter operation | Higher initial cost | Regular cleaning, occasional motor and speed control maintenance |

Flow Rate and Horsepower Considerations

Choosing the right swimming pool pump involves understanding the crucial relationship between flow rate, horsepower, and your pool’s specific needs. Getting this right ensures efficient cleaning, clear water, and a longer lifespan for your equipment. Incorrectly sized pumps can lead to wasted energy, inadequate filtration, and premature wear.

The pump’s flow rate, measured in gallons per minute (GPM), directly impacts your pool’s turnover rate. Turnover rate refers to how long it takes for the pump to circulate the entire volume of water in your pool. A faster turnover generally means cleaner water, as contaminants are filtered more frequently. However, excessively high flow rates can be wasteful and put unnecessary strain on your system.

Conversely, a slow turnover rate can lead to poor water quality.

Calculating GPM for Appropriate Turnover

Determining the ideal GPM involves considering your pool’s size and desired turnover time. A generally recommended turnover rate is between 6 and 8 hours, although some experts suggest aiming for a slightly faster turnover, especially in warmer climates or for pools with high usage. To calculate the required GPM, you’ll need to know your pool’s volume in gallons.

You can often find this information on your pool’s construction plans or calculate it using online calculators that require pool dimensions.

For example, let’s say you have a 15,000-gallon pool and you want an 8-hour turnover. First, convert the turnover time into minutes: 8 hours

– 60 minutes/hour = 480 minutes. Then, divide the pool volume by the turnover time in minutes: 15,000 gallons / 480 minutes ≈ 31.25 GPM. Therefore, a pump with a flow rate of around 31.25 GPM would be suitable for this pool.

Remember to always round up to the nearest available pump GPM to ensure sufficient turnover.

Horsepower Requirements and Influencing Factors

The pump’s horsepower (HP) determines its power and ability to move water. Several factors influence the necessary horsepower, including pool size, plumbing configuration, and filter type. Larger pools naturally require more powerful pumps to achieve the desired turnover rate. Complex plumbing systems with many bends and narrow pipes increase resistance, demanding higher horsepower to maintain flow. Different filter types also present varying levels of resistance; for instance, sand filters typically require slightly more horsepower than cartridge filters.

To determine the appropriate horsepower, consider the GPM calculated earlier and the total head loss in your system. Total head loss represents the combined resistance from pipes, fittings, and the filter. This value is often expressed in feet and can be calculated using specialized plumbing calculators or estimated using manufacturer guidelines. Higher total head loss requires a more powerful pump (higher HP).

Pool manufacturers or professional pool service providers can usually help determine the appropriate total head loss for a specific setup.

For instance, a larger pool with complex plumbing and a sand filter will require a higher horsepower pump compared to a smaller pool with simpler plumbing and a cartridge filter, even if both pools need a similar GPM. Consulting a pool professional or using online pump sizing calculators that account for these factors is highly recommended to ensure you select a pump that is both powerful enough and energy-efficient.

Plumbing and Filtration System Integration

Choosing the right swimming pool pump is only half the battle; seamlessly integrating it into your existing plumbing and filtration system is crucial for optimal performance and longevity. A poorly integrated pump can lead to reduced efficiency, increased energy costs, and even damage to your equipment. Understanding the interplay between your pump, plumbing, and filter is key to a healthy and enjoyable pool.Proper plumbing size directly impacts pump performance.

Undersized pipes create excessive friction, hindering water flow and forcing the pump to work harder, potentially leading to premature wear and tear. Conversely, oversized pipes might not provide enough resistance, causing the pump to run inefficiently. The correct pipe diameter ensures a smooth, consistent flow of water, maximizing the pump’s efficiency and lifespan. A qualified pool professional can assess your system and recommend the appropriate pipe sizes for your specific pump and pool configuration.

Filter Type and Pump Selection

Different filter types—sand, cartridge, and diatomaceous earth (DE)—present varying degrees of resistance to water flow. Sand filters offer the lowest resistance, followed by cartridge filters, with DE filters providing the highest resistance. This resistance impacts the pump’s required horsepower. A sand filter will require a less powerful pump compared to a DE filter for the same pool size and desired flow rate.

Selecting a pump with insufficient horsepower for a high-resistance filter will strain the pump and reduce its lifespan; conversely, an overpowered pump for a low-resistance filter will be inefficient and wasteful. Matching the pump’s capabilities to the filter’s resistance is essential for balanced system operation.

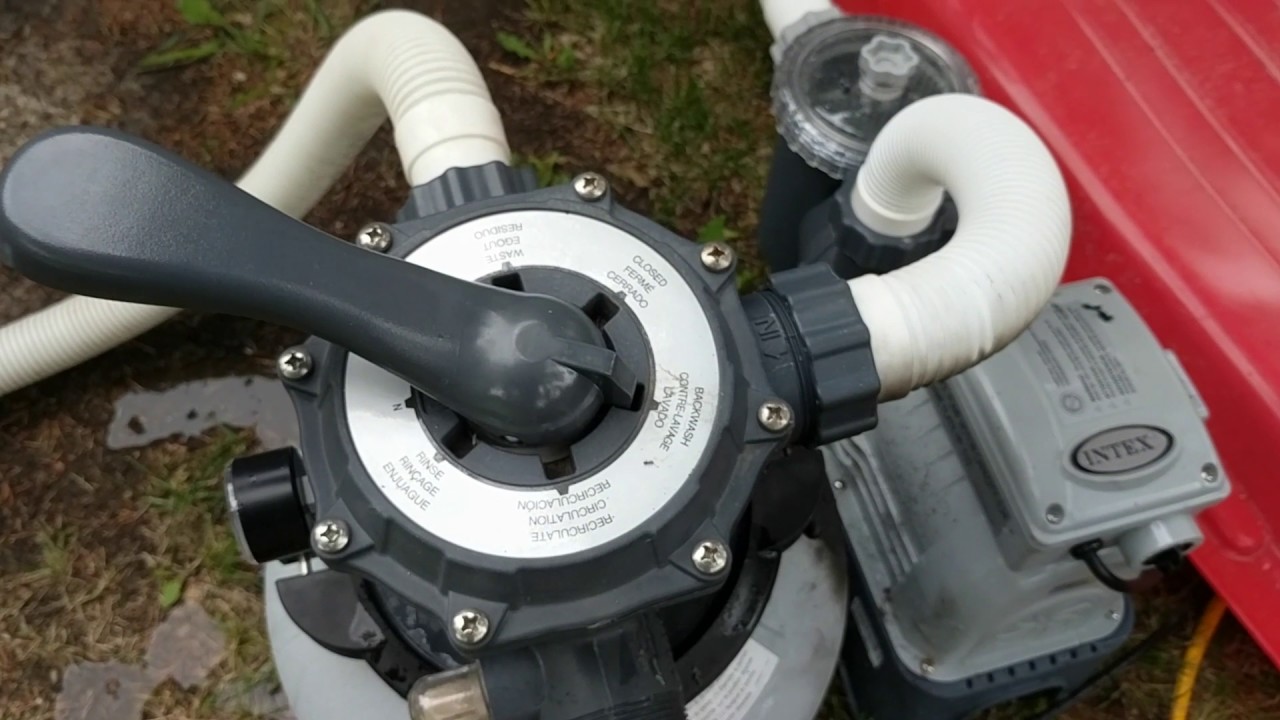

Valves and Fittings for Optimized Efficiency

Valves and fittings play a critical role in managing water flow and pressure within the filtration system. Properly sized and strategically placed valves allow for easy isolation of sections for maintenance or repairs, preventing the need to drain the entire pool. Furthermore, they enable adjustments to flow rates, optimizing the cleaning cycle and extending the filter’s lifespan. Leaking or corroded fittings can significantly reduce pump efficiency and even cause damage to the pump itself.

Regular inspection and replacement of worn fittings are essential for maintaining optimal system performance and preventing costly repairs.

Essential Considerations for Integrating a New Pump

Before installing a new pump into an existing system, several crucial factors must be considered:

- Pump Compatibility: Verify that the new pump’s voltage, amperage, and flow rate are compatible with your existing plumbing and filter.

- Pipe Sizing: Ensure that the pipe diameters are appropriately sized for the new pump’s flow rate to avoid excessive friction or insufficient resistance.

- Valve Functionality: Check all valves for proper operation and replace any worn or damaged components.

- Fitting Integrity: Inspect all fittings for leaks or corrosion and replace as needed.

- Filter Media Condition: If replacing a pump, assess the condition of your filter media (sand, cartridge, DE). Old or clogged media will reduce efficiency regardless of the pump’s capabilities.

- Professional Installation: Consider professional installation to ensure proper integration and avoid potential problems.

Budget and Maintenance

Choosing a pool pump involves more than just technical specifications; the budget and long-term maintenance costs are crucial factors to consider. Understanding these aspects will help you make an informed decision that aligns with your financial capabilities and long-term commitment to pool ownership. This section will explore the price ranges of different pumps, typical maintenance needs, and the potential for cost savings through energy efficiency.Pump prices vary significantly depending on the type, horsepower, and brand.

Generally, single-speed pumps are the most affordable, followed by two-speed pumps, and then variable-speed pumps, which command the highest prices. Horsepower also impacts the cost; a higher horsepower pump will naturally be more expensive.

Pump Price Ranges and Maintenance Costs

As a general guideline, a single-speed pump with 1 horsepower might cost between $200 and $500, while a comparable two-speed pump could range from $400 to $800. Variable-speed pumps, offering greater energy efficiency, typically start around $600 and can exceed $1500 depending on features and horsepower. These prices are estimates and can vary based on retailer, brand, and specific model features.Maintenance requirements also differ between pump types.

Single-speed pumps require regular cleaning of the impeller and strainer basket, as well as occasional lubrication of motor bearings. Two-speed and variable-speed pumps have similar maintenance needs, but may also require occasional capacitor or electronic component replacement, which can be more costly. Annual professional servicing is recommended for all pump types to ensure optimal performance and longevity. The annual cost of maintenance, including parts and labor, could range from $50 to $200 depending on the pump type and the need for repairs.

Long-Term Cost Savings with Energy-Efficient Pumps

While variable-speed pumps have a higher initial cost, their energy efficiency translates to significant long-term savings. These pumps adjust their speed based on the pool’s needs, consuming less energy compared to single-speed pumps that constantly run at full speed. For example, a variable-speed pump could reduce energy consumption by 70% or more compared to a single-speed pump of the same horsepower.

This translates to substantial savings on your electricity bill over the life of the pump, often offsetting the higher initial investment within a few years.

Five-Year Cost Comparison

The following table provides a simplified comparison of the estimated costs over a five-year period for different pump types. These are estimates and actual costs may vary depending on electricity prices, maintenance needs, and pump usage.

| Pump Type | Initial Cost | Annual Operating Cost | Annual Maintenance Cost |

|---|---|---|---|

| Single-Speed (1 HP) | $300 | $200 | $75 |

| Two-Speed (1 HP) | $600 | $150 | $100 |

| Variable-Speed (1 HP) | $1000 | $50 | $125 |

Additional Features and Considerations

Choosing a pool pump involves more than just horsepower and flow rate. Several additional features and considerations can significantly impact your pool’s performance, maintenance, and overall enjoyment. Understanding these factors will help you make a more informed decision and ensure you select the best pump for your specific needs.

Self-Priming Capabilities and Built-In Timers

Self-priming pumps automatically draw water from the pool, eliminating the need for manual priming. This is a convenient feature, saving you time and effort, especially if your pump is located some distance from the pool or experiences occasional airlocks. Built-in timers allow you to schedule pump operation, optimizing energy efficiency and reducing running costs. For example, setting the timer to run the pump during off-peak hours can lead to substantial savings on your electricity bill.

Furthermore, a timer allows for controlled filtration cycles, ensuring consistent water quality without continuous operation.

Pump Placement and Accessibility for Maintenance

The location of your pool pump is crucial for both efficient operation and easy maintenance. Ideally, the pump should be placed close to the pool’s filtration system for minimal plumbing and reduced friction loss. However, it’s equally important to ensure the pump is easily accessible for regular maintenance tasks like cleaning the strainer basket, inspecting the impeller, and performing occasional repairs.

A pump tucked away in a cramped space can make even routine maintenance a significant hassle. For example, if the pump is located in a poorly ventilated area, overheating can occur, reducing its lifespan and efficiency. Easy access allows for timely maintenance, extending the pump’s operational life.

Noise Levels Associated with Different Pump Types

Different pump types produce varying noise levels. Variable-speed pumps, while generally more energy-efficient, tend to be quieter than single-speed pumps. Single-speed pumps often run at a constant, higher noise level. The impact of pump noise on pool enjoyment is significant; a noisy pump can disrupt relaxation and conversations near the pool. Consider the proximity of your pump to living areas and choose a model with a noise level that aligns with your comfort preferences.

For instance, a quieter variable-speed pump placed further away from the house will minimize noise disturbance compared to a louder single-speed pump located near a patio or deck.

Components of a Typical Swimming Pool Pump

A typical swimming pool pump consists of several key components working together to circulate and filter pool water. These include the motor, which provides the power; the impeller, a rotating component that creates suction and pressure; and the pump housing, which encloses and protects these internal parts. The strainer basket, located at the pump’s intake, prevents debris from entering and damaging the impeller.

Imagine a cross-section of the pump. The electric motor sits at the top, connected to the impeller shaft. The impeller, shaped like a fan with curved blades, sits within the pump housing. As the motor spins the impeller, it creates a vacuum, drawing water in through the strainer basket. The water then flows through the pump, propelled by the impeller’s rotation, and exits through the discharge port.

The pump housing protects the internal components from damage and provides a secure seal to prevent leaks. The entire assembly is typically constructed from durable materials like cast iron or reinforced plastic to withstand the constant pressure and exposure to water and chemicals.

Final Thoughts: How To Choose The Right Swimming Pool Pump For My Needs

Selecting the right swimming pool pump is a crucial investment that impacts both the performance and longevity of your pool. By carefully considering your pool’s size, your budget, and the various pump types available, you can ensure crystal-clear water and efficient operation. Remember, a well-chosen pump isn’t just about immediate performance; it’s about long-term savings on energy and maintenance.

So take your time, do your research, and choose the pump that best suits your needs – your pool will thank you for it!

Question & Answer Hub

What’s the difference between a single-speed and a variable-speed pump?

Single-speed pumps run at one constant speed, while variable-speed pumps adjust their speed based on demand, saving energy and reducing noise.

How often should I replace my pool pump?

The lifespan of a pool pump varies depending on usage and maintenance, but generally, they last 10-15 years. Regular cleaning and maintenance can extend their life.

Can I install a new pump myself?

While some DIYers attempt it, installing a pool pump is often best left to professionals to ensure proper plumbing and electrical connections.

What is a pool pump’s turnover rate, and why is it important?

Turnover rate refers to how many times the pump filters the entire pool’s volume in a given time period (e.g., 8 hours). A faster turnover rate generally means cleaner water.

How do I know if my current pump is undersized or oversized for my pool?

Signs of an undersized pump include poor water circulation and filtration, while an oversized pump can waste energy and increase noise.